With my 3D printer I can print all sorts of stuff off the internet from free sites like Thingiverse. Well I had a unique item I needed….and I couldn’t find any sort of bracket/support/mount to exactly fit the specifications.

So one lazy Saturday I tried solving this. You see……since about 2003 I’ve always had a scooter to get around downtown, since driving a car and parking it are quite chore in heavy traffic or during large events. This is my current scooter is a 2013 Aprillia Scarabeo 100cc. Here it is sitting in the garage:

However my little friend here tends to be the victim of clumsy motorists every once-in-a-while, and gets knocked over whilst they park. This does minimal damage, but each impact generally takes one of the front blinker lights out. You can see both of them hanging off by the cords like rabbit ears here:

Unfortunately they’ve BOTH now been broken in such a way that I can’t just screw them back in, and no repair shops have any easy solution for this. In the past I was just supergluing the hell out of the connections to keep them solid. The superglue is a GOOD solution, but the small surface area for adhesion mixed with a 7″ blinker arm that is constantly bouncing around means it only lasts for a few rides before giving way:

WELL…….I thought: “I OWN a 3D printer!! And I sooorrt of know how to 3D model very very basic shapes. Lemme make my own custom mount!”

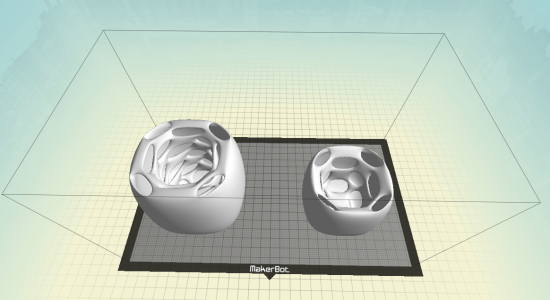

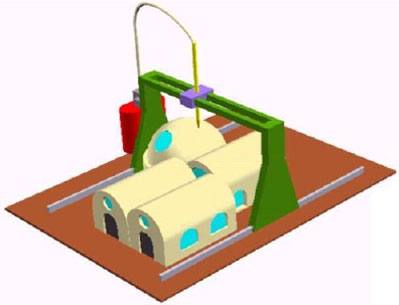

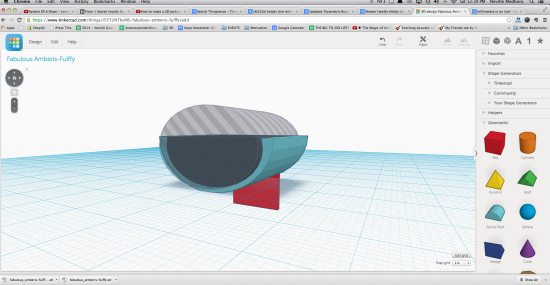

So I hoped onto my favorite browser-based design tool that’s super-easy to use called TinkerCad. I slapped a few shapes together and came up with this design:

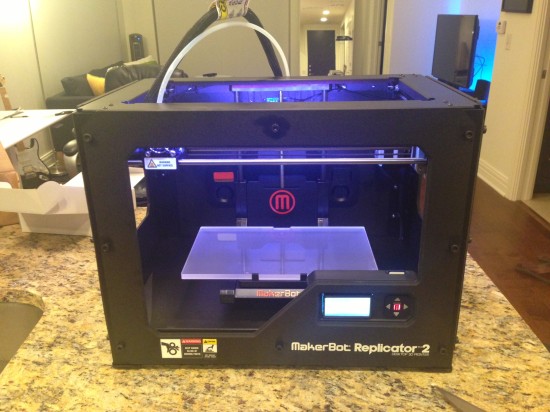

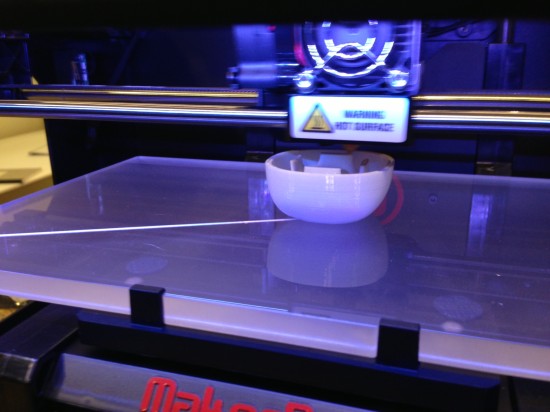

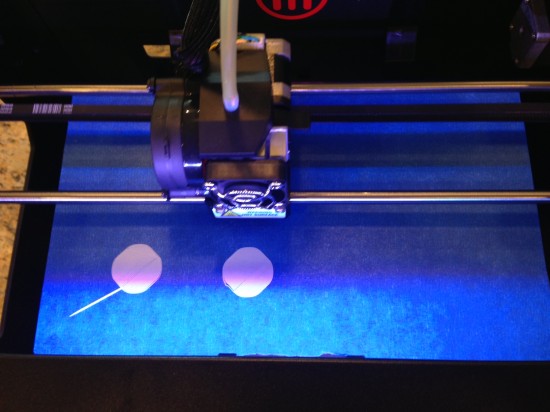

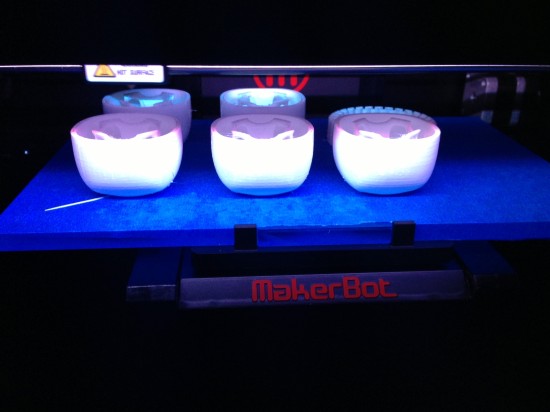

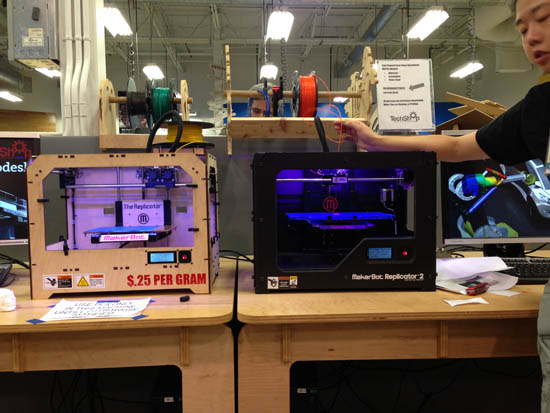

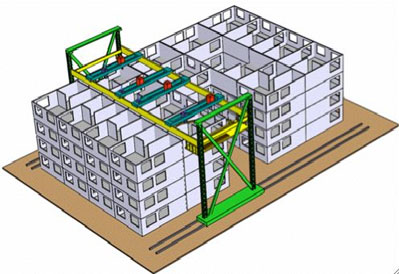

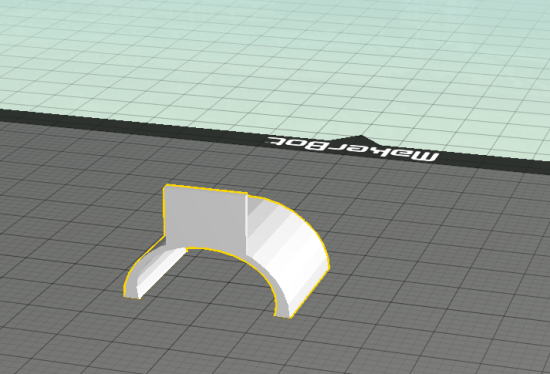

I then ported it over to the MakerWare software (that prints directly to my MakerBot Replicator 2), and scaled it to the size I needed, and mounted it upside down for easier printing:

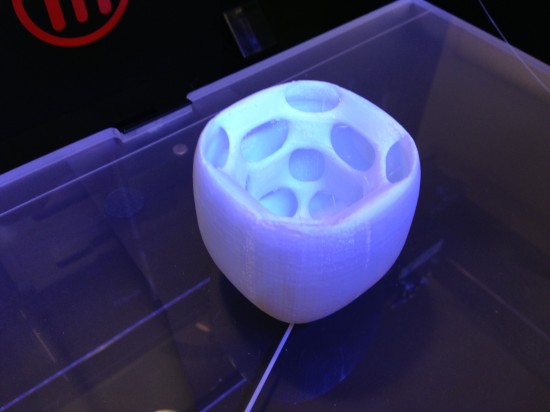

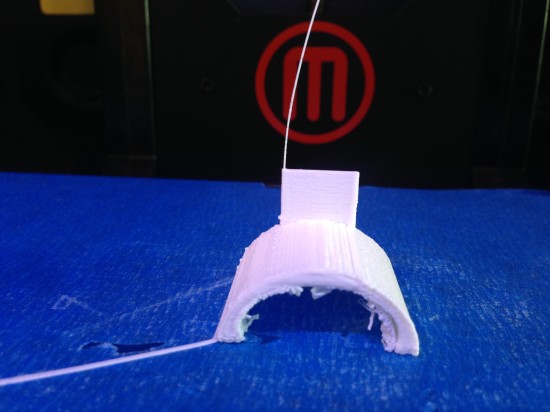

Well the first version came out horribly as you can see below. The wall thickness was too small, I didn’t use supports, and in general the whole structure was too small to fit around the entire blinker arm:

On a side note, I had to make several trips up and down the elevator to get from my apartment to the garage for measurements…..so I just brought the whole damn scooter up to my place……good decoration eh? :-)

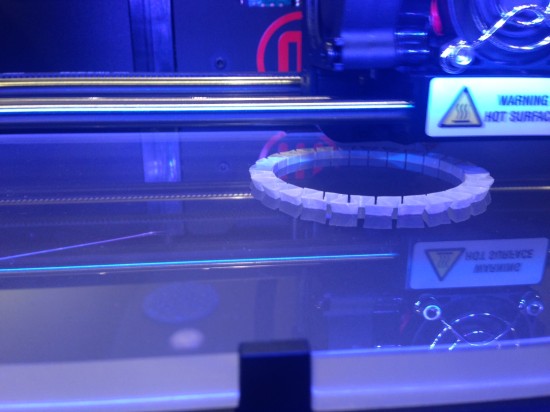

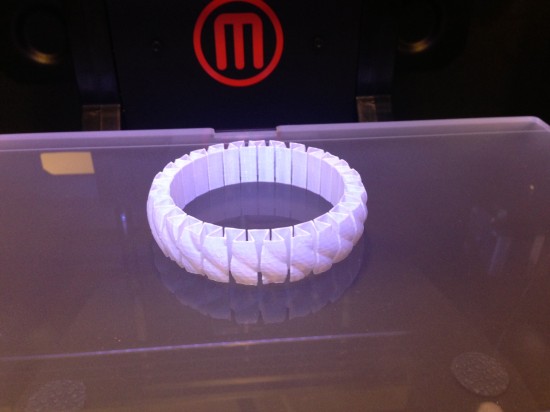

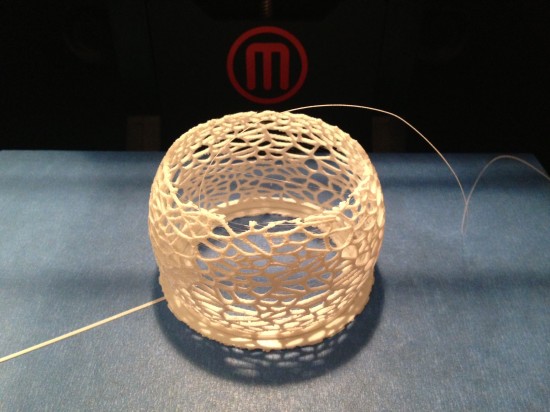

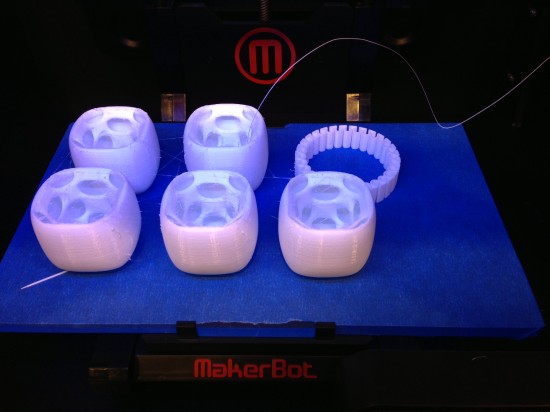

So on Version Two of my custom mount I did some re-tooling of the mount on TinkerCad to beef up the wall thickness, and got a successful print:

Unfortunately my measurement estimations were a bit too small so this one failed also:

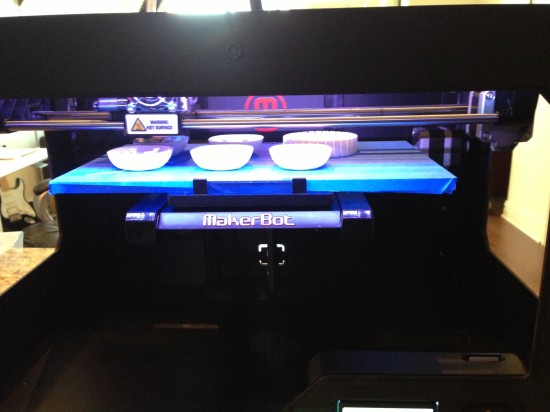

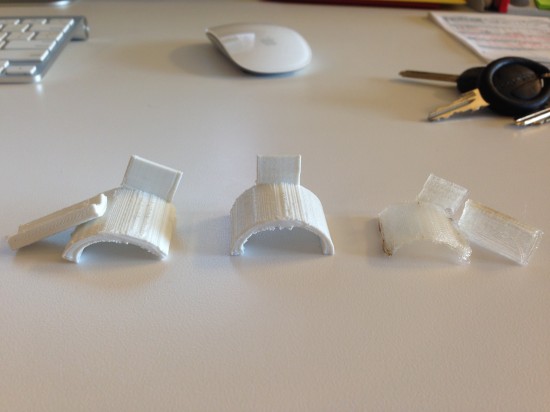

The 4th variation of the mount I designed finally worked. Here are the three failed experiments:

Eventually I got it shaped “kinda” right….and with some modifications (shaping the bracket by warming it up under hot water and padding the arm with tissue paper) I was able to get both blinker arms back in operation. It’s kind of a ghetto patch…..but not bad for a first-time custom design of a functional support :-)

Thanks 3D printer!

This isn’t as cool as my 3D Printed Chess Set, but it makes my scooter road-legal again!

P.S. In the off-chance that someone else in the universe has a broken blinker arm on an Aprilia Scarabeo, here’s the .STL file so you can print your own mount!

scarabeo-mount.stl